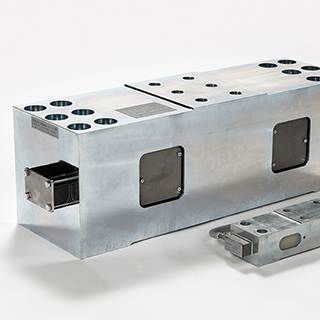

SensiQ WB 40 t weightbeam Schenck process Vietnam

Cân SensiQ WB 50 t Schenck process Việt Nam

Weightbeam SENSiQ WB 100 t Schenck process

Thông tin sản phẩm tại hãng: Schenck process

Thông tin sản phẩm tại TMP: Schenck Việt Nam

Các ứng dụng của sản phẩm:

Ladle turret scale

Ladle transfer car

Scrap basket, roller and tundish scales

Silo and bin weighers

Chức năng, đặc điểm:

Simple and cost-effective installation through direct bolted joint with the connecting structure without moving parts

No additional straps or hold down bolts required

High functional safety and availability, even with frequently unavoidable impact loads and constraining forces

|

|

|

|

|

|

WB 40 t |

|

WB 50 t |

|

|

WB 100 t |

|

WB 150 t |

WB 200 t |

|

WB 600 t |

|

Ref |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nominal load |

|

|

Emax |

|

40 t |

|

50 t |

|

|

100 t |

|

150 t |

|

200 t |

|

600 t |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Limit load (with Lq = 0.15 x LI) |

|

LI |

|

100 t |

|

120 t |

|

|

210 t |

|

290 t |

|

360 t |

|

1000 t |

|

|

|

|

Limit load = max. safe load |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Breaking load (with Lq = 0.15 x Ld) |

|

|

Ld |

|

160 t |

|

200 t |

|

|

350 t |

|

480 t |

|

600 t |

|

1200 t |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. permitted lateral load |

|

|

Lq, max |

|

40 t |

|

50 t |

|

|

85 t |

|

120 t |

|

150 t |

|

400 t |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nominal characteristic value |

|

|

Cn |

|

0.95 mV / V |

|

1.08 mV / V |

|

|

1.38 mV / V |

|

1.57 mV / V |

1.63 mV / V |

|

1.40 mV/V |

|

Emax |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Compound error |

|

|

Fcomb |

|

±0.1 % *) |

|

|

|

±0.07 % *) |

|

|

|

0.1 % *) |

|

Cn |

|||

|

|

||||||||||||||||||

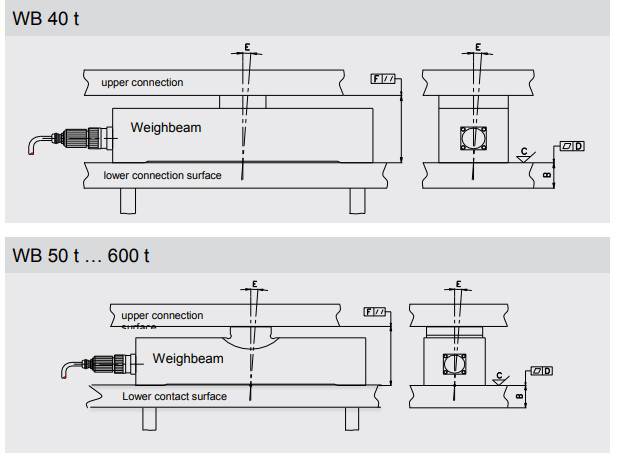

Bản vẽ SENSiQ WB 600 t công nghệ cân Schenck process

Material selection "A": Construction steel is used of at least S355 grade must be used.

Operating thickness "B": This depends on the stiffness of the overall construction. The operating thickness of the connect surfaces must be at least 40% of the the weighbeam height.

Surface quality "C": The average peak-to-valley height required of the contact surfaces is 6.3 μm.

Flatness "D": The maximum permissible flatness tolerance of each contact surface is 0.05 mm.

Angle error to the vertical axis "E": The permitted maximum value for the angle deviation of the contact surface to the vertical axis is ± 2° in both planes.

Plane parallelism "F": The upper and lower contact surfaces to the weighbeam must be plan parallel to each other within at least 0.1 mm.

About Schenck Process

Schenck Process is the global technology and market leader in applied measuring technology. We make processes work in all areas of industry throughout the world. For us that means improving our customer processes in terms of reliability, efficiency, and accuracy. Combining outstanding equipment and extensive process knowledge, we develop and manufacture innovative solutions for weighing, feeding, conveying, screening, automation, and air filtration applications. We focus on the needs of our customers and support them through the whole lifecycle of a product. For more information, visit schenckprocess.com

Schenck Process customers love the simple and cost-effective installation of these SENSiQ® WB weighbeams. They connect directly inside the given structure without moving parts and transmit all disturbance forces and moments with minimal measuring value interference. Plus, SENSiQ® WB weighbeams function entirely maintenance-free in the harshest conditions, offering high long-term stability and high reproducibility.

Typical applications are ladle turret, ladle transfer car, scrap basket, roller table and tundish car scales as well as silo and hopper weighers.

The full SENSiQ® WB loadcell range now includes 11,5 t, 15 t, 25 t, 40 t, 50 t, 100 t, 150 t, 200 t and 600 t rated capacity types.

Một số order code của sản phẩm

|

Design |

Order number with straight plug outlet |

Order number with lateral plug outlet on the right |

||

|

|

|

|

(see drawing above) |

(cf. page 5) *) |

|

|

WB 40 t |

V711375.B03 cân định lượng |

V758596.B01 |

|

|

|

WB 50 t |

V711375.B13 |

V758596.B11 |

|

WB 100 t |

V711375.B23 |

V758596.B21 |

||

WB 150 t |

V711375.B33 |

V758596.B31 |

||

WB 200 t |

V711375.B43 |

V758596.B41 |

||

WB 600 t |

V711375.B53 |

V758596.B51 |

||

|

|

|

|

|

|

Spare part: |

V090162.B01 |

— |

||

Schenck Process, the global market leader in measuring and process technology solutions, is proud to announce the latest generation of its SENSiQ® WB weighbeam technology.

For more than 30 years Schenck Process weighbeams, now all branded SENSiQ® WB, have been the standard for tough weighing tasks, especially in the heavy duty and harsh environment of steel production.

The latest release from Schenck Process is the world’s highest capacity loadcell with a nominal capacity of 600 metric tonnes for installation by simple bolting into the given steel structure. This makes it ideal for hopper scales with a total weight of up to 2,500 tonnes as well as for hoppers in train loading systems.

The original, proven over more than 30 years, optimized to the latest state of technology

Expanded to an operating temperature from -40 °C … 180 °C

High precision with a maximum combined error of ±0.07 % across the entire temperature range

Extremely robust and maintenance-free, IP68

6-wire circuit

Integrated sensor for temperature monitoring and compensation, and integrated overvoltage protection

Separate installation of the connecting cable through plug connection on the Weighbeam, also available as hinged plug outlet

Đại lý Schenck process tại Việt Nam

SensiQ WB 40 t weightbeam Schenck process Vietnam

- AT2E VIETNAM

- IBA VIETNAM

- DMN WESTINGHOUSE VIETNAM

- Mark-10 VietNam

- WISE CONTROL VIETNAM

- MATSUSHIMA VIETNAM

- Brook Instrument VietNam

- CEIA VIET NAM

- Đại lý phân phối Okazaki Việt Nam

- Nireco VietNam

- TEK TROL VIETNAM

- TECLOCK VIETNAM

- KELLER VIETNAM

- CEMB VIETNAM

- CS INSTRUMENTS VIETNAM

- REDLION VIETNAM

- PCI INSTRUMENT VIETNAM

- TDK-LAMBDA VIETNAM

- KOGANEI VIETNAM

- DWYER VIETNAM

- BIRCHER VIETNAM

- BROOK INSTRUMENT VIETNAM

- BECKHOFF VIETNAM

- BEIJER ELECTRONICS VIETNAM

- DAIICHI ELECTRIC VIETNAM

- FOX THERMAL INSTRUMENTS VIETNAM

- IPF ELECTRONIC VIỆT NAM

- LAND INSTRUMENTS VIETNAM

- MASIBUS VIETNAM

- MEHRER VIETNAM

- MATSUI VIETNAM

- NOVOTECHNIK VIETNAM

- OHKURA VIETNAM

- PENTAIR VIETNAM

- PAULY ELEKTRIK VIETNAM

- PILZ VIETNAM

- RADIX VIETNAM

- REDLION

- ROTORK VIETNAM

- RIELS VIETNAM

- SOLDO VIETNAM

- FIREYE VIETNAM

- VIBRO METER VIETNAM

- AUTROL VIETNAM

- Đại lý Frigortec Việt Nam

- KIEPE VIETNAM

- EUROSWITCH VIETNAM

- FOTOELEKTRIK PAULY VIETNAM

- Đại lý DFE USA

- Đại lý Aichi Tokei

- Đại Lý Flow Technology Việt Nam

- Đại lý Tester Sangyo Việt Nam

- Đại lý Goldammer Việt Nam

- Đại lý phân phối Pressure Tech

- Đại lý Me-systemse Việt Nam

- Đại lý Klopper Therm tại Việt Nam

- ĐẠI LÝ RECHNER SENSORS

- ĐẠI LÝ TAIHEI BOEKI

- ĐẠI LÝ HYDROSERVICE VIỆT NAM

- ĐẠI LÝ PHÂN PHỐI FUKUDEN JAPAN

- ĐẠI LÝ LAPAR TẠI VIỆT NAM

- Đại Lý Radix Ấn Độ

- ĐẠI LÝ MAXCESS VIỆT NAM

- DEUBLIN TẠI VIỆT NAM

- Đại lý Avio Việt Nam

- Đại lý Ringspann

- Đại lý Montech Việt Nam

- Đại lý GF Việt Nam

- Đại lý Endress + Hauser

- Đại lý Pro-face

- Đại lý SPOHN + BURKHARDT

- ĐẠI LÝ INTORQ

- Đại lý TEMA Việt Nam

- Đại lý Van Gemu

- Đại lý Bruel & Kjaer Vibro

- Đại lý Young Tech

- Đại lý Labom

- Đai lý Sensorex

- Đại lý Kamui Việt Nam

- Đại lý Pfeuffer

- Đại lý Baumuller

- Đại Lý Knick

- Đai lý Valve Hirose

- Đại lý ECDI Viêt Nam

- Đại lý Conch

- Đại lý phân phối ASHCROFT tại Việt Nam

- Đại lý Amarell

- Đại lý Elco-Holding

- HELUKABEL VIET NAM

-

Trực tuyến:1

-

Hôm nay:433

-

Tuần này:4754

-

Tháng trước:13929

-

Tất cả:3076214

Giao hàng miễn phí.

Giao hàng miễn phí. Làm việc các ngày trong tuần.

Làm việc các ngày trong tuần. Bảo hành 12 tháng.

Bảo hành 12 tháng..jpg)